Cold Chain Monitoring

Fridges, freezers and cold cabinets

See how SenseAbility makes the most sense of your cold-chain assets!

By placing sensors into your fridges, freezers and cold cabinets we can monitor the temperature continuously.

Read on to see how SenseAbility make this information work for you to automate record keeping for regulatory compliance, help to avoid costly food spoilage events , and even advise you on maintenance priorities to make sure your refrigeration investment is working as efficiently as possible for you !

Continuous monitoring of fridges and freezers allows you to see at a glance how they are performing. Alerts can be generated for unusual activity or overheating, and daily reports can automatically be sent to you to provide a permanent immutable record for food safety regulation compliance - without you having to lift a finger!

For peace of mind...

We can send notifications if the temperature is heading beyond permittable ranges for your fridges and freezers. The same approach can also be used on hot food display cabinets with appropriate temperatures.

Notifications can be e-mail, text or even phone calls!

Receiving notifications means you can reduce the risk of costly spoilage events due to equipment failure or human error.

Having such measures in place may also potentially reduce insurance premiums.

Compliance made easy!

We can send you reports on a scheduled basis that give you an instant permanent record of your fridge temperatures for regulatory compliance.

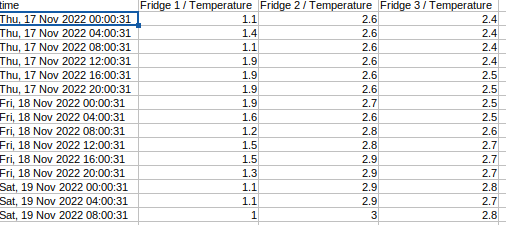

These can be set to show records at various intervals - for example : twice a day , or every four hours. Or if you want we can send you every temperature reading taken throughout the day!

They can be sent to you on a daily, weekly or monthly basis - or combinations thereof.

Here is an example of a temperature report - in this case the report is providing sample readings every four hours for 3 fridges - so you have all your information recorded neatly and easily accessible for food safety compliance.

SenseAbility makes even more sense!

For energy efficiency and reducing energy costs...

By analysing the temperature data we gather from your cold chain devices we are also able to give you information about unit efficiency, running costs and provide pointers to help identify potential problems and improve the overall efficiency and utilisation of your cold-chain assets.

Get in touch if you are interested. We're friendly, we're local and we're ready to help you and your business.

info@senseability.uk

By analysing the duty cycle of your fridges and freezers we are able to evaluate the efficiency of each unit and also point to potential areas of concern. In the example above, Fridge 1 is highlighted due to it's excessively high warming rate - suggesting a possible seal or insulation problem - in turn making this unit considerably more expensive to run

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.